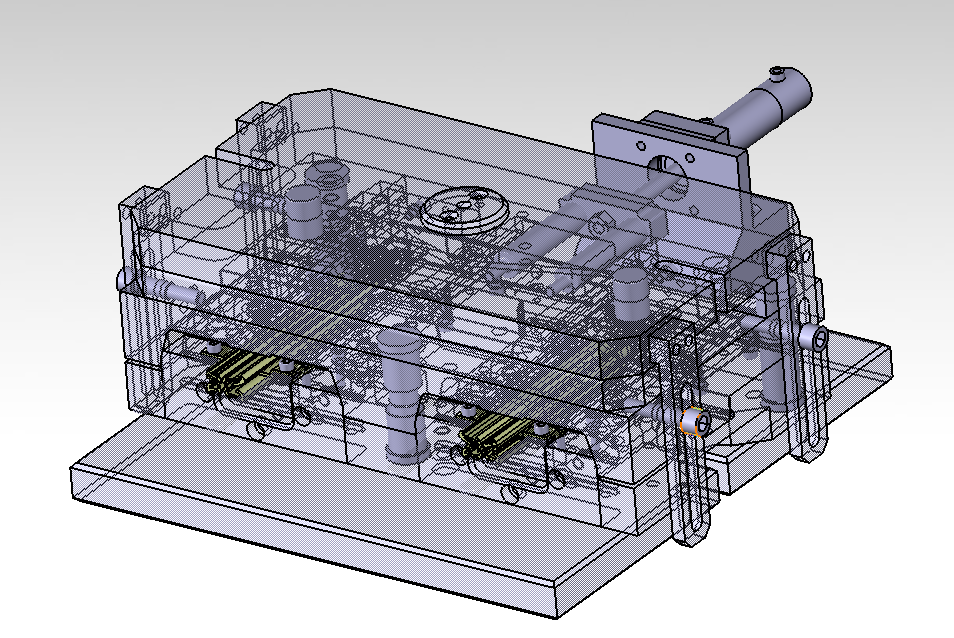

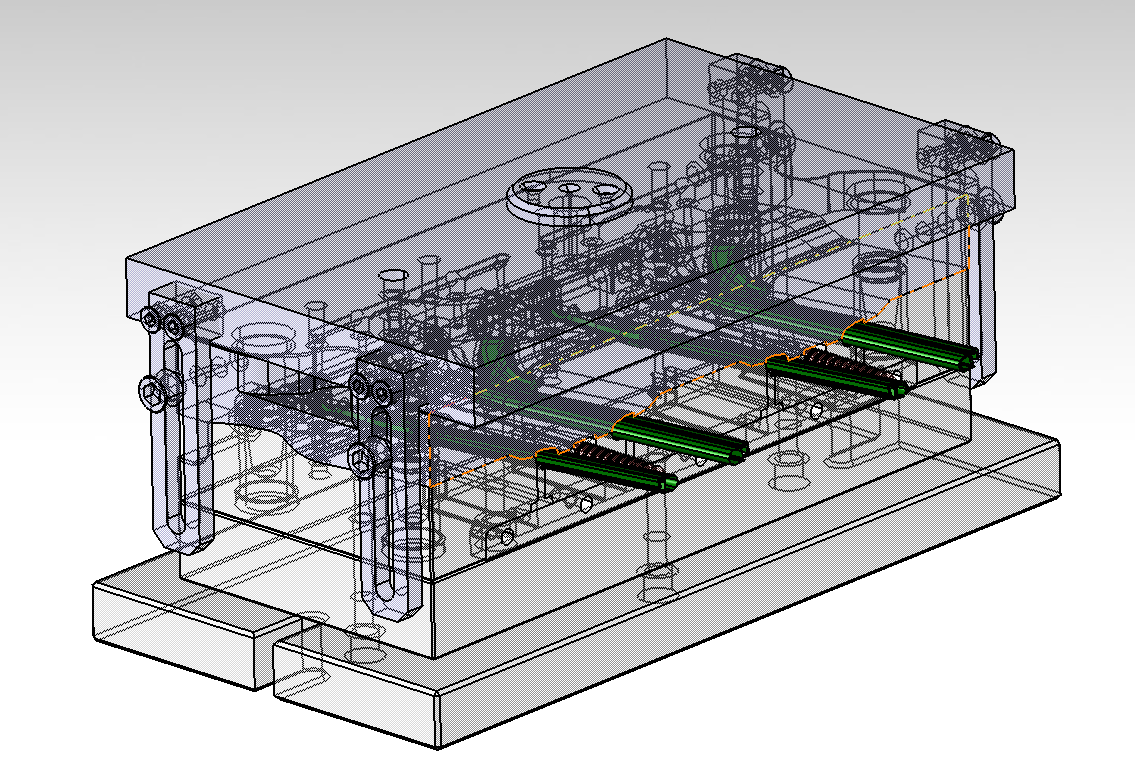

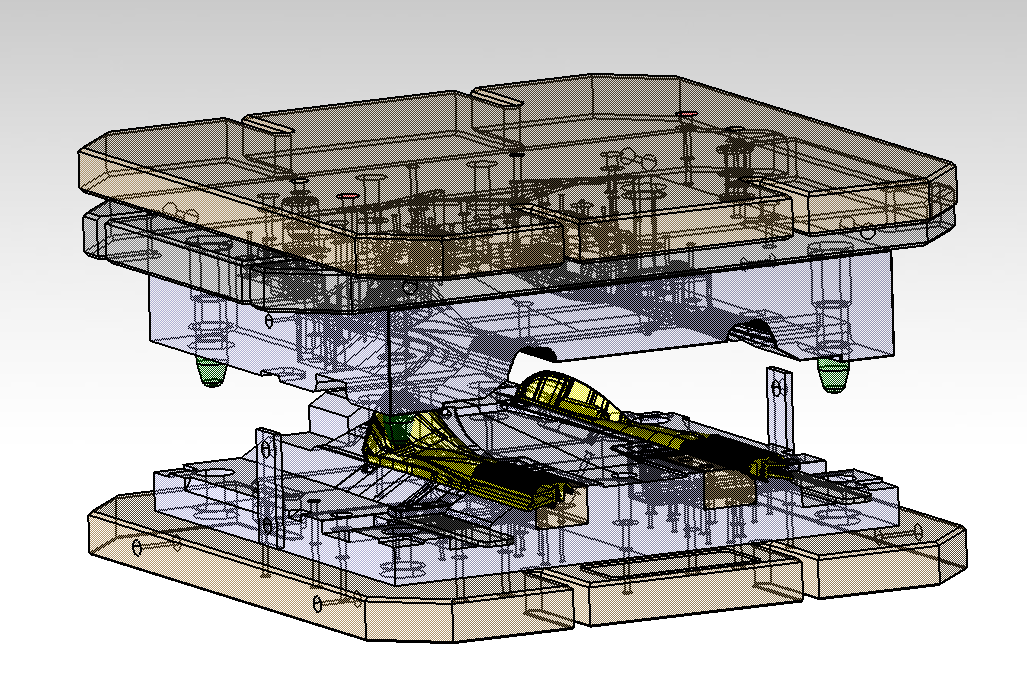

Die

Generally, Extrusion dies are made of two part:

1- The parts of the die which is responsible for uniform flow of material from extruders to the plate form.

2- The form plate, which is responsible for the final formation of the fluid flow.

Basically, the dimensions of the products depend on the geometric of the extrusion dies. In order to design the extrusion die, based on the rheological properties of the used materials, the depth of the flow paths must be designed in such a way that, while achieving a steady flow, not only the same pressure drop in all flow paths is obtained, but also as much a uniform pressure and speed as possible is achieved at the output of the form plate.

Temperature, cure time, tolerance, and shrinkage are other parameters that affect the design. The design expertise of this company is a combination of design science and comprehensive experience that complicated products with highest quality is its result.