Pouygostar has 10 years experience in developing and manufacturing Elastomer gaskets for the tunneling industry. They are made of sophisticated and high-grade rubber compounds quality to meet the high standards and requirements with regard to durability and project life expectancy.

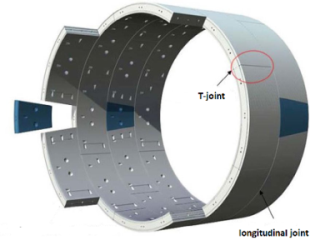

A segmental lining made up of reinforced concrete segments possesses numerous longitudinal and T-joints. These joints have to be sealed against the maximum water pressure that affects the tunnel tube. This takes place by means of Elastomer gaskets, which are installed in the continuous grooves of the segments.

Elastomer rubber gaskets are used to provide long term water tightness in joints of concrete segments.

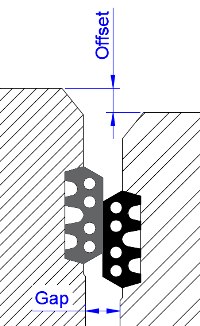

Gaps and offsets between segments are tightened by compression of a pair of gaskets

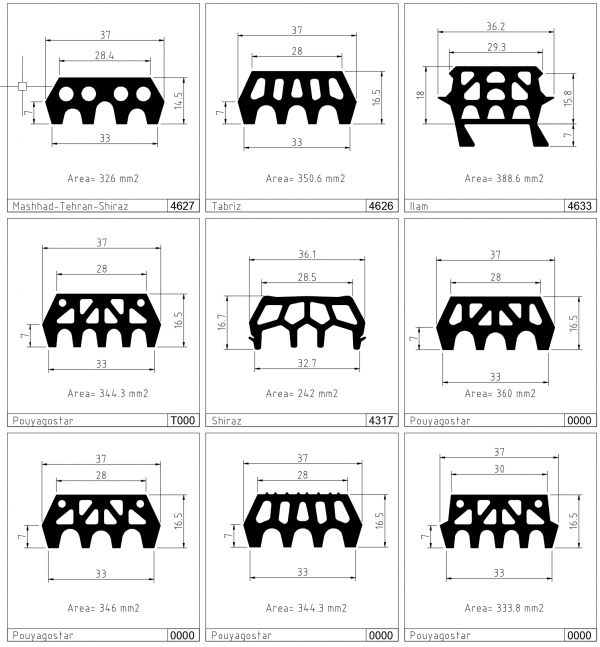

The complex section of the gaskets is designed to provide the energy within the seal, generating the sealing function once the segments have been assembled, whilst minimizing closure forces. Pouyagostar offers a range of gaskets to suit various applications and specifications. In addition, its team of technical engineers have the experience and detailed knowledge to design gaskets for unique conditions. Their experts also prove the gasket in its dedicated test facility, which replicates the segment assembly, build conditions and sealing pressures.

Pouyagostar has the certification of laboratories and production lines’ quality according to the STUVA Recommendations for Testing and Application of sealing Gaskets in segmental Linings.